Product introduction

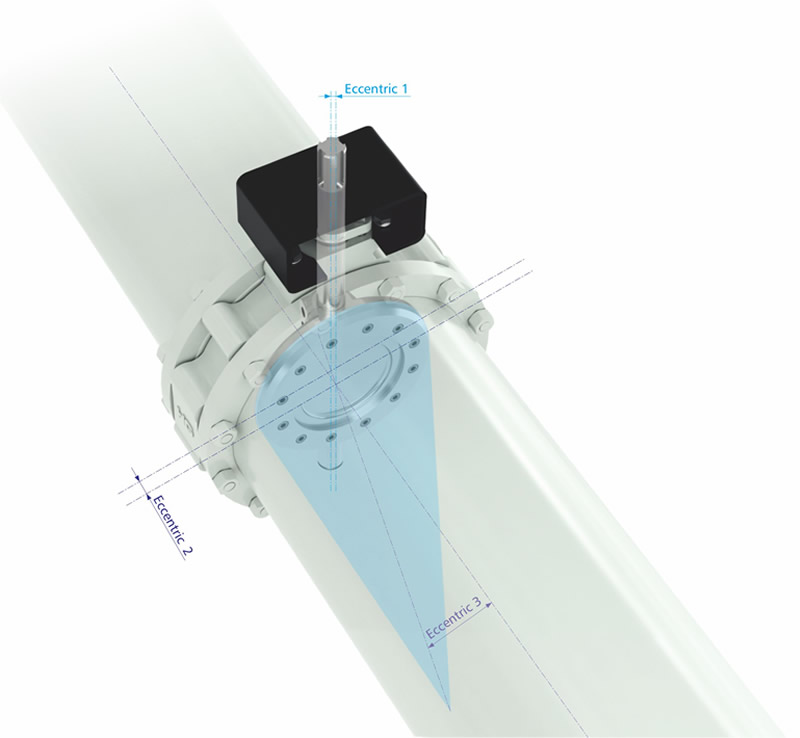

Triple-eccentric butterfly valve adds another unique angle offset on the double-eccentirc butterfly valve to allow the disc to seal against the seat with no friction during the 90 degree‘s opening and closing process. It provides a more cost-effective solution to services require high temperature, high pressure or low temperature. Triple-eccentric butterfly valve is widely used in the pipline system of metallurgy industry, power industry, petrochemical industry, water and sewer system, and municipal construction requires strict medium control.

Extreme Temperature Range

Uniform thickness body, suitable for extreme high/low temperature service range from -196°C to 815°C.

Intelligent Manufacturing

Flexible automatic production line High precision machining process, interchangeable valve parts

Superior Sealing Performance

New innovative patent applied to produce metal to metal bi-drecitonal sealing butterfly valves with the highest sealing performance.

Low operating cost

Extreme low wear during disc opening and dosing process increases product life and reduces maintenance cost.